Automation

Boatloaders (Cantilever Furnace Loading)

Bruce maintains support for the older Bruce boatloaders (7670s and 7680s), the Amtech Systems boatloaders (IBAL and current models) and continues the ability to integrate their mechanical loaders into the controls of other OEM.

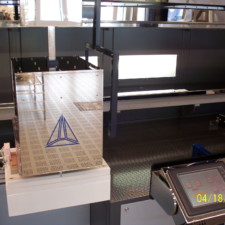

(NEW) 7770 Boatloader: Back-mounted loader designed to replace the 7670 and 7680 series boatloaders from Bruce Technologies. It is also a replacement design for the Amtech loader used for the now obsolete IBAL and Atmoscan loader mechanicals. Integrates into boatloader controls of Bruce Technologies and other furnace OEMs.

Duradrive & Duradrive Controller: High-end, controls and mechanicals design for both 200mm and 300mm loading requirements.

S300 Automation (Loading to the Paddle)

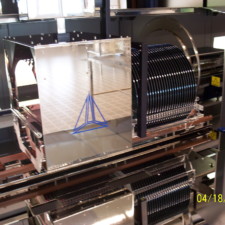

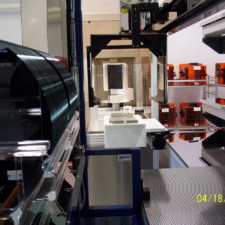

The S-300 automated multiple boat horizontal furnace cantilever loading system is a low cost system designed to assist the fab operator in safely loading and unloading wafer boats to all cantilevers on a furnace stack. Operators place boats onto the load platform at an ergonomically correct height eliminating the need for operators to climb ladders or perform the repetitive motion of loading wafer boats onto the silicon carbide paddle. Load times are typically less then 3 minutes. Control and setup is through a single color flat panel touch screen, instructions are in plain English.

The S-300, mounts directly onto the load station and is compatible with any furnace and cantilever system. Using casters and quick disconnect latches the S-300 can be quickly removed from the load station to allow for maintenance.

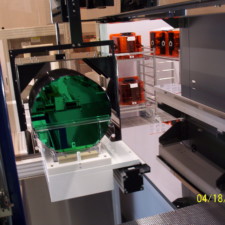

Wafer Transfer Machine (R2D Automation)

Comet series of state-of-the-art systems open new paths of innovation applied to wafer handling and storing. Throughout the world, our service centers provide today’s best automation tools to the semiconductor industry from diffusion/wet to packaging process and photovoltaic applications.

Shuttle (S300 to Wafer Transfer Machine Integration)

For a complete operator’s hands off solution, Bruce does offer a shuttle system that will transfer a completed wafer boat from the WTM directly to the S300 main platform. The shuttle is mounted onto the load island and sits directly inline between both equipment. Unfortunately, this is not a retrofit and would require specific set up and software communication between equipment. Please contact Bruce Technologies to see if this solution would work for your application.

Door Closures: CVD or ATM

Heat Tamer: Auto-doors simply designed to prevent heat from the process tube from affecting the hardware or electronics. Integrates into boatloader controls of Bruce Technologies and other furnace OEMs.

Process Door Closures: Auto door closure designed for specific process requirements such as POCL3 and other CVD processes.

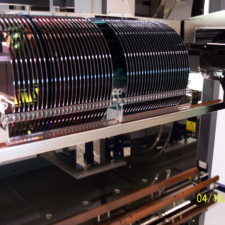

Atmoscan

Over the past 20 years, the Atmoscan is a closed cantilever system used in production with over 1000 units installed worldwide. The Atmoscan’s first use was to exclude O2 from the wafer environment during the push/pull portions of the thermal cycle. This was critical in limiting native or uncontrolled oxidations during load insertion and to stabilize surface states (Qss) upon withdrawal from the furnace. In it’s era, the Atmoscan was enabling technology for many applications. As more Atmoscans were installed, other advantages became apparent, such as better temperature uniformity (particularly during push/pull), higher throughput due to higher push/pull temperatures, and larger load sizes.